On 14 and 15 February in New Delhi, Namrata Sharma’s Global Print Konnect brought together suppliers of inkjet heads, technologies and consumables to bump up the manufacture and assembly of digital inkjet output devices and presses in India. In the meetings with the media and local manufacturers, Seiko Instruments, Kao Chimigraf, Meteor, People & Technology, and Trijet took part.

Inkjet printing technology provides possibilities for new design styles and workflows, short production runs, sustainable printing environments, quick response time, and customization. The technology can be adapted to print on a large variety of substrates including paper, ceramics, tableware, textile, or packaging printing.

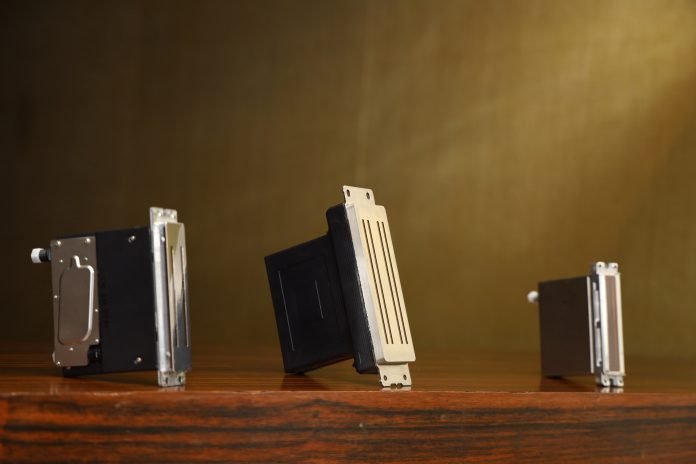

According to Aliasgar Eranpurwala, head of the inkjet printheads department, at Seiko Instruments, sharing knowledge is of utmost significance when talking about any development and with inkjet, there are multiple possibilities. However, maintenance and upgradation of printheads is the first consideration to be taken seriously. Since over-drop or under-drop can both impact one’s final product it is always advised to stock extra heads to timely accommodate printing requirements. He said, “The health of an inkjet press depends on how well it is maintained in a timely fashion for the jetting to be smooth and precise.”

Roberto Campos Orgaz, project manager at People & Technology commented on the curing technologies and chemical developments for cleaning printheads for a variety of inkjet inks such as UV, oil-based, solvent-based, and/or water-based inks. His presentation illustrated the problems that could arise with ink clotting printheads and how this is a severe issue in the consistent industrial use of the technology.

Orgaz said, “Generally when a printing defect occurs consistently, it leads to a spiralling blame game. The printhead maker will blame the ink, the ink provider will blame the maintenance of the machine, and so on, and amid all the confusion the production will come to a halt. Inkjet technology cannot prosper with a lemon-squeeze approach and clotting can lead to several distortions in printing. Even the viscosity of the ink can have complications which is why UV and Near-infrared (NIR) curing technologies are gaining more attention.”

According to Tri Tulidhar director of Trijet, while ink is the blood and the machine is the body the printhead is the heart whose purpose is to pump blood. If the pumping is more or less than necessary it creates a challenge and the final product will not be what was originally intended. He explained that inks and printheads are a merger or combination of chemistry with physics together with a little bit of mechanics.

He said, “The rheological properties of ink may depend on different parameters such as deformation, processing time, processing rate, temperature, and more. The application should determine the combination of physics, chemistry, and mechanics required and the fine-tuning to be administered for reliable changes and results. The mechanical comes in with drive electronics that push the ink for the right drop, place, and time.”

Kao Chimigraf has come up with a new concept for deinking inkjet inks from flexible films also known as thermo switch polymers which Nessan Cleary has reported in our pages. The idea is to use a change in water temperature to trigger a chemical reaction that switches the polymer, which could be in the ink – thus the ink instead of binding to the substrate would be repelled by it, allowing it to float separately for easy recycling of the films.

Francois Aguilar, Kao’s chief commercial officer says that the key to success will be the existing recycling streams and systems. This thermo switch polymer system will be shown as a concept at this summer’s Drupa show in Düsseldorf.

Any printing system to be industry efficient and successful requires the use of several technologies. Although there are a large number of print head manufacturers globally there are currently none in India. However, the development of inks and assembly into devices and presses is growing and Global Print Konnect presented a collaborative network of suppliers that can assist manufacturers in the selection of inputs, technologies and suppliers for applications that they see as potential markets.

A taste of ink rheologies, devices, jetting combinations and drive electronics and maintenance expertise is on offer and the resulting insight should be that there are no shortcuts. The industry meeting indicates that the suppliers are interested in quickly growing the Indian inkjet economy. They are prepared to work collaboratively to speed up the establishment of an ecosystem for developing and guaranteeing the performance of digital inkjet devices, presses and consumables.