In 1961, the late Chandra Prakash Jain founded Chandni Industries at Barhi-Sonipat, as a candle manufacturer. The company diversified into playing cards in the 1970s, eventually becoming one of the industry’s dedicated producers in that segment by 1984. Vipul Jain has been with the firm since 1994, which now produces 25,00,000 playing card packs every month, in a factory with 30,000 square feet of built-up space situated on a 1,800 square meter plot of land.

Chandni Industries further diversified to monocarton production at the outset of the Covid-19 pandemic two years ago. The company’s production assets include Heidelberg SM74 and a Heidelberg SM74 with coater presses, and a Heidelberg Suprasetter CTP driven by Heidelberg prepress workflow. There are also several local machines including coaters from Alpna and Auto Print.

“Currently, our company is placed as one of the leading playing card producers of North India, due to our belief ‘Outperform – Simplify – Inspire.’ We are familiar with paper and board packaging due to our existing business. Hence, we could start the packaging business with our current set-up,” says Jain.

Chandni Industries saw several shifts in the consumer market during the pandemic. In the early days, it saw a rise in the current product portfolio, and as the pandemic continued, it

saw printing innovation play a more significant part, even in its playing-card business.

Existence depends on innovation

Jain remarks on his company’s need for diversification, “Today, existence is primarily dependent on innovation, and thus, we want to diversify. We built an in-house printing plant for various print applications, which prompted us to decide to get into the paperboard packaging sector. We’ve started a packaging printing business, and we’ve invested in a DGM folder-gluer because of their team’s packaging expertise.”

Jain decided that the DGM converting equipment was the best fit for its market needs after assessing the other available solutions. As the company moved into packaging, DGM provided both ideas and advice and its professional support and infrastructure in India demonstrates the company’s commitment to the country’s packaging industry.

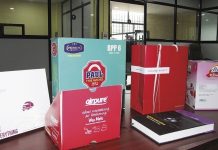

Chandni now produces all types of cartons such as lock-bottom, litho-laminated and conventional monocartons. It also produces Braille embossed cartons, clamshells, and trays. It has reached a substantial production level with the capacity to produce 90 lakh to 1 crore (9 to 10 million) cartons each month.

The packaging industry remains among the fastest-growing industries in the Indian economy. Before the pandemic started, the packaging industry was steadily gaining, but the pandemic seems to have given it an opportunity to leap forward in its growth. With the increased consumption of packaging many companies have scaled up and many commercial printers have diversified into packaging. Thus Chandni Industries is one among many of the diversifications to carton printing and converting and as its packaging work deepens, it is targeting customers from the pharma, cosmetic and FMCG industries to expand its production.

Having successfully diversified to packaging, the company quite naturally is thinking of its next steps. Among its plans is a greenfield expansion which includes more infrastructure, equipment, and technology. Jain says, “The packaging sector is competitive and I believe that innovation unlocks new horizons.”