Manroland Sheetfed India hosted an industry gathering and press conference on 1 February at the Crowne Plaza in Greater Noida. The industry event was attended by Manroland Sheetfed’s existing and potential customers, several industry leaders, and the trade press.

Manroland Sheetfed is owned by Langley Holdings, a family-owned company that is completely debt-free and has traditional values regarding its investments. Its press manufacturing plant in Offenbach Germany employs 750 workers with a worldwide strength of 1,450 employees, which includes its sales and service organizations in 45 countries including India.

The Offenbach plant is spread over 70,000 square meters, comprising its foundry, mechanical and electrical component manufacturing, and assembly line. Known for making high-quality offset presses over its long history, it has several thousand presses installed in the US, central Europe, and Asia.

In our interaction with Mirko Kern, CEO of Manroland Sheetfed, and Deepak Walia, managing director of Manroland Sheetfed India, Kern revealed that he started as an apprentice with Manroland Sheetfed in 1989, and continued working for the company for 23 years in various positions before leaving the company, which he rejoined in 2023.

He spoke of India as one of the growing markets for commercial and packaging printing with great potential for development. Manroland Sheetfed India is still building up to grow in this dynamic market, he said. “We are currently working on various projects in India. Many customers are having conversations with us about our machines at Printpack. At the same time, we are strengthening our service and spare parts departments. We want to be a reliable service partner to our customers,” he said.

Kern added, “We are strong on meeting the different size requirements of Indian printers with the various models in medium and large sizes of the Manroland Sheetfed R700 and R900 Evolution presses for offset and commercial printing and packaging.”

The seventh stop of the Manroland Sheetfed World Tour took place in India coinciding with Printpack, with an open house at Galaxy Offset in Ghiloth Industrial Area from 2 – 5 February. At the new Galaxy plant, potential and existing customers witnessed the R700 Evolution 7-color plus coater UV press in action. The next stops of the World Tour will be in Mexico and the UK.

“We are targeting orders for six Manroland Sheetfed machines in India in FY 25-26,” Kern said, adding that some orders are in the pipeline and installations of the new machines will begin from March 2025. “As the Manroalnd Sheetfed team from Germany is visiting India, we plan to visit our Indian customers and listen to their experiences with our machines to gain an in-depth understanding of the specific requirements of Indian customers,” he added.

In his presentation, Walia said “At Manroland Sheetfed India, we believe that innovation, collaborations, and strong partnerships drive the future of print. I would like to highlight that there will be two machines coming soon to India.”

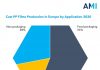

Speaking of the global outlook, Kern said, “The commercial printing market, though shrinking, is still a huge market globally with 2-4% of the total offset printing market. The packaging segment, on the other hand, will grow in the future. So, we are looking at both commercial printing and packaging segments.”

Jens Kaiser, head of sales, Manroland Sheetfed, and Stefan Stillger, head of product management and R&D shared insights on the advanced technology of Manroland Sheetfed R700 and R900 Evolution presses. While the R700 Evolution caters to the 75 x 106 cm sheet size, the R900 Evolution deals with 106 x 145 cm sheet size with the largest press size going up to 130 cm x 185 cm making it the largest format sheetfed offset press available. The automation features of these presses enable shorter make-readies, plate changes within a minute, and inline color control and register control. Kaiser showed several samples showcasing the printing effects produced by Manroland’s Evolution with LED inks, UV inks, coatings, and metallic shades.

Stillger commented that the Ecology Pilot on the presses can measure the energy consumption for a particular job, an entire shift, or the annual energy consumption of the press including its accessories. Another unique feature of the presses, the Triple Flow system is designed to optimize ink flow during production.

Robin Pradel, head of product management and print services, and Fulvio Zechini, CEO and head of the sales department of Zechini, also spoke. “Zechini provides solutions for bookbinding, paper converting, and rigid boxes for packaging. Zechini’s products and solutions can manufacture hardcover books, luxury boxes, collapsible boxes, and children’s picture and board books. The machines can produce 100 to 4,000 books an hour with spines as thick as 7 cm. For luxury packaging, we also have short-run machines to produce high-quality products.”

At the conclusion of the event, Peter Rego, director of sales at Manroland Sheetfed India, noted, “The printing industry is constantly evolving with new technology, innovations, and advancements always coming up. Print is here to stay.”