The global ALPLA Group is setting the course for further growth in injection molding by establishing the ALPLAinject division. By concentrating all injection molding expertise and capacity under this brand, the plastic packaging specialist is increasing efficiency, speeding up the market launch of new products, and unlocking new market segments.

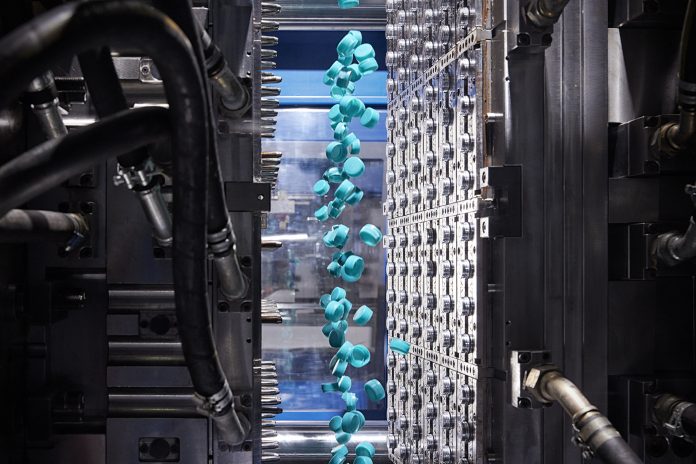

ALPLAinject stands for high-quality injection-molded parts such as closures, caps, jars, and multi-part packaging components such as pumps or deodorant sticks. With this new division, the international ALPLA Group is setting the course for further growth. The ALPLAinject brand brings together all human and technical resources in this area in one central organizational structure. It comprises a total of three core technologies – injection blow molding and compression molding in addition to injection molding – as well as global toolmaking, development, and sales.

Standardized processes, centralized product, and technology development; and shorter distances will ensure greater flexibility and efficiency in the future. “With ALPLAinject, we are focusing on the specific requirements of the dynamic injection molding market. We combine technological expertise and regional market knowledge, promote the global roll-out of innovative processes, and enable our customers to bring new products to market faster,” emphasizes the new ALPLAinject managing director Michael Feltes, who had already been Business development director in the injection molding section of the Group since October 2022. The global headquarters of ALPLAinject are located at the ALPLA headquarters in Hard. There are also global teams in all nine regions of the ALPLA Group.

Injection molding drives growth

ALPLAinject manufactures roughly 60 billion injection-molded parts per year at 43 plants around the world. The division has more than 600 machines and systems. As a pioneer in packaging solutions and recycling, ALPLA also relies on technological innovation. ALPLAinject scores highly with its decades of experience in lightweight, alternative, and recyclable materials; and energy-saving production facilities.

‘The injection molding sector offers enormous potential and is one of our strategic growth drivers. The competitive market environment requires maximum cost-effectiveness and flexibility. As its injection molding division, ALPLAinject will continue to ensure our competitiveness in the future,’ says ALPLA CEO Philipp Lehner with conviction. The new division reports directly to the CEO.