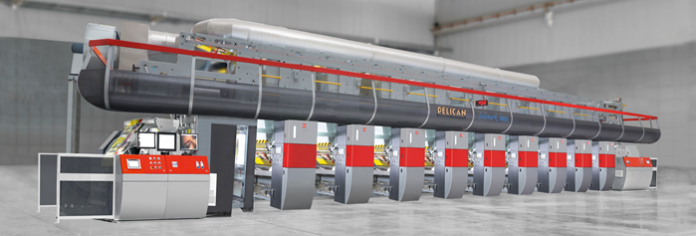

AB Polypacks, a West Bengal-headquartered one-stop shop for a wide range of flexible packaging solutions, recently added a 9-color Solomark ELS 6450 rotogravure press from Pelican Rotoflex to its portfolio. The company had earlier added a turret slitter from Pelican.

With its manufacturing facility spread over 1.5 lakh square feet of land in Howrah near Kolkata, the company, which started its journey in 2006, provides a wide range of flexible packaging solutions, including collation shrink films, shrink labels, wrap-around labels, laminates, and all kinds of pouches, under one roof.

The Solomark 6450 has a maximum web width of up to 1300 mm, with a web tension range of 60 to 400N and a reel diameter of 1000 mm. Chinmay Kumar, co-founder of AB Polypacks, emphasized its high energy efficiency with lower power consumption and less waste. “It is user-friendly with better operational ease with better print quality and higher productivity,” he said.

According to Kumar, the machines present in the plant’s arsenal for printing, lamination, blown films, shrink labels, and pouching are what set the company apart from its counterparts.

The printing unit, apart from the new Solomark 6450, is equipped with four more high-speed rotogravure printing presses. It has expertise in a diverse range of materials, ranging from polyester and PVC to PET-G, shrink film, BOPP film, foil, and paper.

The blown polyethylene film unit at the plant has a production capacity of 10,000 metric tonnes per annum. The company says it takes pride in manufacturing the best quality three-layer collation shrink film and poly films of a wide variety for lamination.

Speaking about the blown film unit, Kumar said, “Our W&H Optimex extruder provides excellent mechanical strength, and a completely automated machine provides precise operations. The thickness controller ensures easy downgauging and reduces micron variation with minimum wastage.” The major suppliers of plastic granules to the plant are HPL, IOCL, Dow Chemicals, and Borouge.

To provide high-quality packaging material, the manufacturing unit is equipped with fully automatic corona treatment machines such as Nordmeccanica. It is a combi line in which simultaneously solventless and base facility can be utilized.

The pouching unit manufactures various types such as three-sided sealed pouches, central seal pouches, stand-up pouches, pillow pouches, spout pouches, shaped pouches, and various customized pouches as per requirements.

With the entire gamut of flexible packaging solutions under one roof, the company offers its products to the food packaging, liquid packaging, healthcare, and agriculture sectors, the household and personal care sectors, and the spices industry as well.

“High barrier properties along with high aroma retention properties of our packaging material make us the supplier of choice to most of the spices brands in the country,” he said. Multinational brands such as Coca-Cola, Pepsico, Hindustan Unilever, Britannia, Parle Agro, Haldiram’s, Pidilite Industries, etc., form part of the company’s key client portfolio.

On the sustainability front, Kumar aims to make solar power the primary renewable source of energy for AB Polypacks by the year 2025. “Through the integration of new technology and machinery, we are wholeheartedly embracing sustainability.” According to Kumar, the company works to reduce waste and energy consumption in the manufacturing process, thereby doing its bit to produce more responsible packaging solutions.