Asahi Photoproducts, a specialist in flexographic photopolymer plate development and a subsidiary of the Asahi Kasei Corporation, is gearing up well for drupa 2024. The company says it wants to ensure that its exhibit in Hall 8b, Stand A13, is a prime destination for anyone participating in the flexographic industry, from brand owners and repro houses to flexographic printing operations.

Scheduled for 28 May through 7 June 2024 at Messe Düsseldorf, Germany, drupa is the destination for forward-thinking owners and managers in the broader printing industry.

“Ever since our company was founded more than 50 years ago,” said Dieter Niederstadt, Asahi’s technical marketing manager, “We have been developing sustainable printing plate materials such as our liquid APRTM resins which are processed with water. Our goal, and that of our parent company Asahi Kasei, is to bring to market products that create for life and living and a more pleasant working environment.”

“With the majority of flexographic platemaking still using solvent-wash processes,” Dieter added, “We will also be helping visitors to our stand at drupa understand how easy the Road to Solvent Zero is, making their operations more sustainable and offering a more pleasant ambient environment for workers. The first step is to switch to reduced solvent plates, such as Asahi’s AFPTM-R CleanPrint plate, which reduces solvent usage by 30% with no need to make any additional equipment investments – simply switch plates and you are on the Road to Solvent Zero.

At drupa 2024, Asahi will share how this is accomplished with three themes.

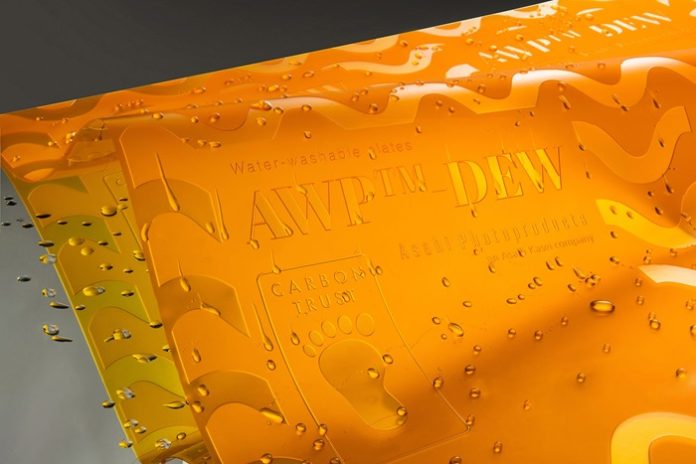

Sustainability: The company says it will help flexographic plate makers and printers along Asahi’s philosophy of the Road to Solvent Zero while reducing water and energy consumption, and improving productivity and quality on press. Its AWPTM-DEW and AWPTM-CleanFlat water-wash plates are certified carbon neutral in collaboration with The Carbon Trust. In addition, visitors to the stand will learn how they can save up to 85% of wastewater usage using the AWP-LOOPTM water recycling unit.

Printing Excellence: The company will display a full range of flexographic plates, including introduction of new plates, designed for printing on paper, corrugated and recycled film. The plates are ideal for using expanded color gamut printing technologies for both printing excellence and increased sustainability, the company says.

Automation and Digital Transformation (DX): At drupa 2024, Asahi will share with visitors the ultimate in automation for flexographic platemaking: CrystalCleanConnect, co-developed with Esko and Kongsberg. This breakthrough system, already installed in several locations around the globe, reduces the platemaking process from 12 steps to 1, reducing labor, minimizing potential for error, and resulting in a press-ready plate. An additional digital service is its remote technical support based on either smart glass or smartphone depending on the customer preference.

Dieter Niederstadt concluded, “We look forward to seeing you at drupa 2024 and working together to journey down the Road to Solvent Zero.”