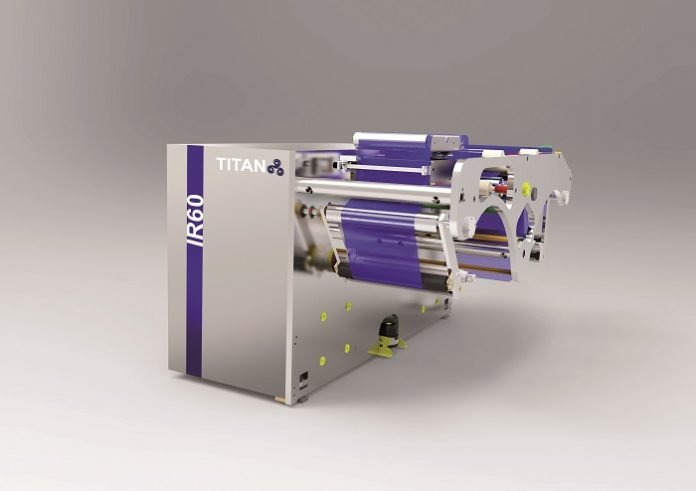

Atlas Converting launched a range of inspection rewinder machines to complement the Titan range of slitter rewinders at the ICE exhibition in Munich in end-March. The IR60, IR135, IR165 and RR165 inspection machines will unwind, inspect and rewind material from 60 cm (24 inch) to 165 cm (65 inch) width material to improve the quality of the mother rolls that go into the slitter rewinder, eliminating the need to stop the slitter and therefore increasing the slitting efficiency and slit quality.

Identifying defects in the web can be done by either by a fully automatic 100% inspection system, manually using stroboscopic systems or by entering multiple stop signals based upon the flag location. The machines are high speed, fully reversible and with the inclusion of splice table the operator can remove all defects greatly reducing waste and time.

Barrie Homewood, sales director for Titan products says, “Real productivity improvements are seen when producing ‘Multilane’ rolls that only require rewinding to a defined length and edge trimming the RR135 and RR165 are ideal work horses freeing up the slitter rewinder to do the multiple lane jobs.”

The IRR135 & IRR165 Compact Inspection machines can also be used to splice together smaller mother roll diameters and deliver a larger mother roll again increasing efficiencies of the slitter. In addition to above features the RR165 with its overhead web path can incorporate additional ‘valued added’ processes such as web laser perforation/scoring and other web treatments. With its brands of Atlas & Titan, Atlas Converting Equipment Ltd. is one of the world’s largest manufacturers of primary and secondary slitter rewinders for plastic films, label stock, laminates and other flexible materials. The company has to date installed more than 2.600 secondary Titan and 1000 Atlas primary slitter rewinders worldwide, with over 250 film slitters exceeding 6 meter (236 inch) in width.