The new process allows printers to achieve astonishing in-line effects and incredible contrast between gloss and matte images simply via the use of a litho plate and a coater. Gloss points of 90 and higher are achievable with a single LED lamp in a ‘wet-on-wet’ process sequence, with a high-powered AMS XP9 Series LED UV lamp located in the delivery.

“Drip-off is one of the ‘holy-grails’ of in-line printing effects for many commercial printers to realize,” said Carsten Barlebo, managing director of AMS EMEA. “Traditionally it required a number of conventional, heat-generating mercury-based UV lamps at inter-station and delivery positions to achieve. Not only was this incredibly inefficient, but quite simply it put the process out of reach for most printers. And as the European and other markets are moving quickly away from UV-lamps and seeking alternatives, LED UV now provides a fantastic solution.”

Advantages of the new effect are not only stunning visually but can be rendered with simple litho plates in-line in a standard offset print unit where the matte contrasting effect is desired. The elements of the image that remain glossy are the non-matte-printed areas. “A further advantage of the process is that the coating has no detectable ‘UV smell,’ a big contrast to traditional UV coating technology on the market,” said Steve Metcalf, president and CEO of AMS.

The new process runs counter to the idea that LED UV cannot be used for in-line coating and finishing effects. “We have now established an entirely new generation of LED UV power and coating development with our partners, which translates to another major milestone achieved and ‘full speed ahead’ for LED UV in the market for top-quality, high-productivity machines,” added Hans Ulland, VP of sales for AMS. “It gives much of the same tactile effect of the latest generation of off-line, inkjet raised print-enhancement presses, but this is done in-line at virtually no additional cost per sheet.”

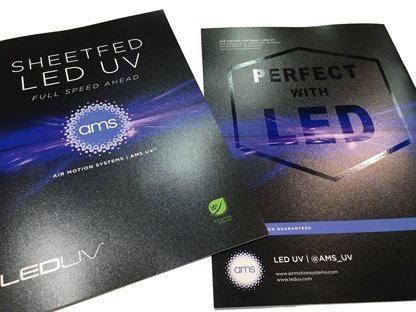

AMS’s LED Drip-Off process is on display at drupa (Hall 14 Stand B71) and was highlighted in the Grafische Palette magazine in Germany, where it was used to create the inside cover for the drupa 2016 special edition. AMS will be distributing numerous samples of the effects on a wide range of materials to printers visiting its stand at drupa.

Packaging South Asia is the cooperating media partner for drupa 2016 which is scheduled to be held from 31 May to 10 June at Dusseldorf, Germany.