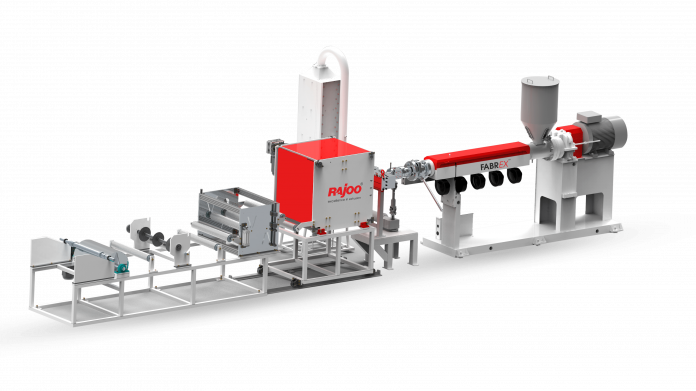

Building on its close to a decade of experience in making spun-bond non-woven fabric extrusion machine, Rajoo extended its excellence in extrusion to build the melt-blown fabric making extrusion machine, to complete its ‘fabric side of the solution.’ The first company in India to do so with machines to create a composite non-woven fabric solution. The challenges faced by the engineering team were only compounded by the global lockdown. Taking this challenge as an opportunity, Rajoo has also built a path-breaking fully automatic N95 mask making machine capable of producing 1 mask every 2 seconds (i.e. 1,800 masks per hour). The automation ensures that these masks are hygienic and produced with minimum wastage as well as minimal human intervention.

The industry has a choice, they could either procure the entire fabric-to-mask solution from Rajoo or just the mask making machine, depending on their needs. The solutions offered are universal! Also, available are machines for the 3-ply masks. The machines are being made available as Rajoo readies itself to execute supplies for a spike of demand. The first batch of orders are already under execution.

Khushboo Chandrakant Doshi, executive director, Rajoo Engineers Limited proudly highlights, “I am happy that we could contribute in our own way to the fight against COVID-19. We are in a position to service industry needs globally. Here, I also wish to acknowledge the stupendous efforts put by Rajoo’s team working efficiently even in this trying situation.” The dynamic nature of healthcare demands presents different opportunities for the processing industry at different times.

These solutions from Rajoo can be easily adapted to address the changing demands with be it surgical; drapes and wraps; sponges, dressings and wipes; bed linens; gowns – for contamination

control and examination; and many more. In fact, from a business perspective, products produced from these machines also find uses in sectors such as personal care and hygiene, home furnishing, agriculture, geotextiles, automotive, filtration, stationery.