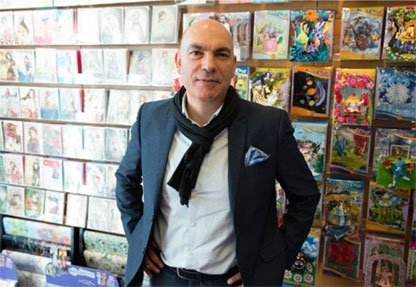

Interview — Neeraj DarganRebuilding Manroland Sheetfed in IndiaSince its acquisition by Langley Holdings in early 2012, Manroland Sheetfed, Germany has been in good financial health. Tony Langley himself is a hands-on manager, and Manroland Sheetfed is now perhaps one of the more viable and sustainable sheetfed press manufacturers with a staff strength of approximately 1,500. Profitable for the past three years, and run as a hands-on company with quick decision-making, its Indian operation is looking to work the same way – it’s looking at print businesses not as commodity producers but as quality operations that can add immense communication value and impact. “That’s why we are building Manroland Sheetfed India on a knowledge and tech support base for our customers,” says Manroland Sheetfed India’s managing director Neeraj Dargan.The Manroland in-line foiler installed at Borkar PackagingDargan goes on to explain, “With the launch of the new 700 Evolution press we have shown our technical understanding of how to optimize high configuration packaging presses. We believe that our customer’s printing and packaging plants have to achieve the value that they are capable of, if they are to be competitive in terms of value addition, quality and especially efficiency. Our customers will find those niche markets where their innovations include a demand for quality. They must offer unique solutions based on real communication and impact needs or what their customer decides to choose and not merely push for available technology. That is true customization.”

In order to optimize the efficiency of its Indian customers, Manroland Sheetfed has introduced its Upgrades and Service kits concept. The idea is to reduce downtime and increase efficiency, helping to reduce the cost of ownership for its users and also to extend the profitable lifespan of a press rather than compelling customers to invest in a new press. “This is where our team will make the difference in India and especially strengthen our existing user base and bring them the latest technology from a company they can trust and are comfortable dealing with,” says Dargan.

Dargan emphasizes that Manroland Sheetfed is globally recognized for its packaging machines especially the 700 series and that its large format presses are another area of strength. Fortunately for the company, the Indian monocarton market is on a high growth path and getting ready for very large format presses. The company has just finished installing a large format used 906 6-color plus coater press at Borkar Packaging. In addition, in-line foiling, a concept that Manroland Sheetfed promoted widely in India several years ago, also seems to be generating interest from packaging printers. Many industry experts consider the Manroland foiling solution to be the best and the first in-line foiler that came into India – was also to Borkar Packaging on a high configuration used press. In conclusion, Dargan says, “With the launch of the new press 700 Evolution and our recent successes globally, the Indian market can be expected to respond positively to the new Manroland Sheetfed organization as its presence is felt on the ground.”