Many birds are known to spot and pick up everyday shining objects, such as pieces of foil wrappers, or metallic buttons, and take them home to place in their nests. A similar instinct is probably hard-wired in all our minds too and nobody seems to understand this better than packaging designers. Writes Deepak Manchanda.

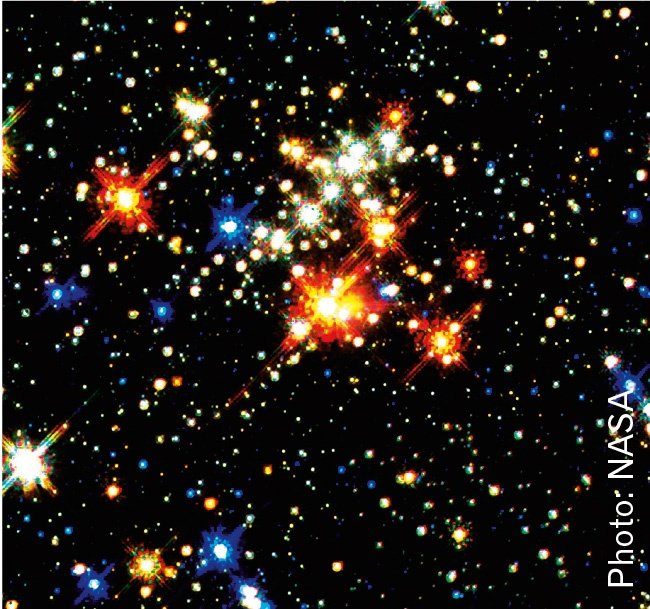

The first objective in today’s crowded communications environment, whether it is packaging, product or service, is to be noticed. In their ceaseless attempts to make packs designed by them to be noticed among the cluttered shop-shelves and to create desire by design, packaging designers need little prompting to bring out their most potent device — shine!

Often, it’s a difficult task given the inherent limitations of media budgets and mass communications as well as the available technological processes. However, for those who possess the knowledge to apply it, there exists the “shine genie” — those magical solutions of vivid colors, textures, foil stamping, embossing, combination processes, holography and other such print finishing effects that have the power to mesmerize the customer and make products leap off the shelves into the buyer’s shopping baskets.

The product’s appearance, enhanced by foil based print finishing, adds high potency “shelf appeal” to separate it from the competition. In a market where products are becoming increasingly homogenous in terms of functionality, this powerful enhancement of the pack design greatly increases the beauty of the packaging to add to its appeal to buyers.

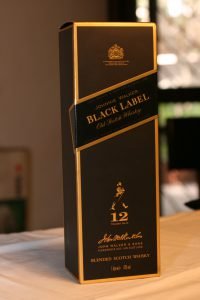

“One of the best examples of how foil-stamped and embossed images work to draw in the consumer is with the wine industry,” says a knowledgeable study by the Foil Stamping and Embossing Association (FSEA), USA. The same study goes on to state that more than 70% of the time when consumers purchase wine, they don’t know the specific brand or type they are going to choose until they reach the aisle. It observes that foil helps a product or package to stand apart and, because of that, it continues to be a popular choice.

Additionally, foil and embossing create a perceived value that the product inside the bottle or package is of the highest quality.

Creating desire by design

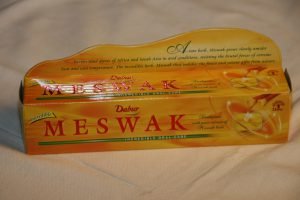

Not only for wines and spirits, foil stamping based print finishing effects are also found to be very popular in many consumer product categories such as high-end cosmetics, hair care, gourmet confectionery and gift sets. The study observes that foil stamping has found very specific niches within the packaging domain, but still offers a great deal of potential in many untried sectors — some of which could be personal care, health and beauty care and even music, entertainment and gaming software. In fact, it is easy to visualize the widest possible acceptability of foil finishes in the broadest possible range of consumer products wherever brand managers look for ways to set their package apart from competition and, being under increasing pressure to gain market share, are willing to spend the extra buck to do so.

Reports of studies by the FSEA have shown conclusively why foil based print finishing is so popular. The study showed that packaging with foil rated more than 80% stronger than packaging without foil in terms of overall appeal, quality value and brand awareness. Foil-enhanced product perceptions translated to an increased purchase interest in more than 70 % of the cases studied. And, the study claimed that 26.7 % of consumers will choose a foil-stamped product over one with a plain label. Add to these statistics additional alternatives for using foil, including the die-less, cold-foil process and applying foil (both cold- and hot-stamped) inline on narrow-web flexo presses and “more feasible opportunities exist than ever before to add foil to consumer packaging,” suggests the study. “Whatever the application, metallic foil conveys a strong and positive image,” continues the study. It is also observed that while foil has an added value perception with high on-shelf visibility, if the foil is not applied correctly, it will impact just as significantly on appearance and quality.

It is clearly established that employing foil decoration and metallic effects for print finishing is one of the most cost effective ways to give packages the eye-catching appeal that brand owners demand. Foil never loses its magic. Foil and other attractive packaging applications have gained such prominence among retail brands today that even products once considered humble are now gleaming from store shelves.

In retail markets, particularly cosmetics and toiletries, labelling is a critical factor in the packaging process and is often a consumer’s first exposure to a product. A product, in order to succeed, must make a memorable impression: linking high quality with reasonable pricing that will reflect the superiority of the product inside. One only has to scan the shelves to see a strongly emerging trend of foil decoration, which is featuring in a plethora of applications including toothpaste tubes and packets of tea.

Application of foil can be done inline on the press or treated as an off-press finishing effect. Either way, metallic effects continue to improve.

Hot foil stamping

The oldest form of foil decoration — Hot Stamping is also known as Foil Stamping or Gold Embossing. It is a relief decoration, process that uses a combination of metal printing plates with raised images, hot stamping foil, heat, pressure and time.

Hot Stamping is the choice of packaging designers mainly because:

- There is no other printing process that can deliver bright metallised finishes that create the desired “twinkle” in the design.

- It is a comparatively simple process compared to almost all other decoration processes and, therefore, requires no special training or skills.

- The process easily adapts itself for use over a very wide range of substrates – paper, board, thermoplastics, leather and textiles.

The oldest form of hot foil application is through the use of a flatbed press. This is still in production today and the quality of the foil stamp is high, as is the customer satisfaction. The press moves the label through intermittently, pausing to stamp the foil by use of a flat die, heat and pressure. The cost of the stamping dies is negligible, which has always been a selling point for these systems. However, they are offline machines, and require preprinted labels to be re-registered and run through them for the stamping. The process can add to labour and production time.

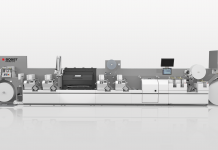

Far more popular, though not ubiquitous, is inline rotary hot stamping, which has been a standard for many years. In recent years, hot stamping units in rotary presses have been becoming increasingly popular. However, the biggest challenge to hot stamping is from cold foil stamping.

The traditional rotary hot foil process is one by which foil is nipped between the substrate and a stamping roll which is heated by oil or electricity and which contains the image to be stamped. Oil heated rollers are said to offer more consistent heat, especially when the unit runs at higher speeds. Heat ranges differ based on the foil being applied. The use of heat to stamp foils on to substrates also determines the speed at which the press will run. If the speed is too much the stamping die will exhaust its heat more quickly and the foil transfer could be incomplete.

Speed may be important for production efficiency but adequate heat transfer to the foil is equally critical to achieve a full transfer of foil. A high machine speed could bring the foil to the point where it is not fully transferring, but showing tiny pinholes.

Cold foil stamping

The cold foil application process was developed towards the end of the 1990’s. In the beginning it had its rough edges (literally) but it is now widely accepted for certain types of print jobs.

Cold foil has made the application of foil available to anyone with a flexo press because it is applied on a standard print station. A special UV curable adhesive is transferred by an anilox roll to a flexo plate containing the image, large or small, and transferred again to the substrate. At that point the foil is nipped to the substrate, and a UV lamp cures the adhesive and bonds the foil to the substrate. The foil is then peeled away from the substrate and the unused portion is taken up on a waste roller. The foils developed today for cold applications are somewhat transparent, allowing the UV to perform its curing duty without metallic inhibition.

Getting cold foil right means having the proper anilox roll, adhesive, curing system and plate. Because converters use their own equipment in various combinations to apply cold foil, results vary. Some have commented that the edges of patterns and letters are not as sharp as those produced by the hot foil process. That’s the result of the wrong tension match between the foil and the substrate, experts say. Tension that is too high in one will cause a mismatch that could be visible when the foil roll is removed from the substrate.

The real magic of foil based print finishing really comes alive when the possibilities of printing on top of holographic foils are explored. Multiple colours, process colours, or full floods of colours can be put on top of these substrates. Most often, silver is used. Once you print on silver holographic or silver foil, you can match just about any color you want.

Cold foil is a growing in acceptance, even more so than hot stamp, because of the design capabilities. In comparison to hot foil, it’s almost plug and play. The process has really opened up doors to applying foil to labels.

The technology behind applying foil to self adhesive labelling is not prohibitively expensive or time consuming — especially when die-less foiling is used. Self adhesive, narrow web production adapts extremely well to die-less foiling, allowing foiling to be used where previously it has not been available, either because of no hot stamp capability or where heat sensitive substrates precluded it. The use of flexo plates instead of expensive engraved rotary dies makes it even more viable.

Flexible stamping

The industry has been turning for several years to the use of flexible cutting dies, which are mounted on magnetic cylinders and are much less costly than solid rotary tools. In the same manner, some are turning to flexible stamping dies.

Replacing a worn stamping die is less expensive than buying a new one, as is manufacturer turnover time and press changeover time. The quality of the image produced by the flexible stamping dies is comparable to that produced by the solid die.

Foil quality

The importance of using a consistent foil for achieving quality results in mettallic foil application simply cannot be overlooked. Consistent foil quality alone will ensure that the release coats are better, the films are not low grade and the foil is super clean with no more than one particle of dust per 1,000 sq ft. All this will in turn ensure that the foil runs smoothly on the machine and ultimately delivers packaging of premium quality with zero defects. Parts of images or letters will not end up getting lost and the transfer runs smoothly from one end to the other.

Foil can be a sustainable choice

Brand packaging managers today have to balance a great deal when analysing their packaging choices. They must balance cost factors and environmental or sustainability issues while still providing eye-catching graphics to get their product noticed. Most experts believe that the sustainability issue is not a fad that will soon disappear but, instead, is a long-awaited movement that is here to stay. Many large retailers have sustainability initiatives in mind or in place. Products are evaluated against a number of metrics ultimately leading towards eco-friendly reductions in the use of natural resources and carbon dioxide output. With the focus on reduce, recycle, reuse and renew, conscious choices are changing the way packaging is designed and produced and how it will be utilised in the future.

Embossing is probably the most sustainable decorating process available, as the embellishment is accomplished through the stretching of the paper stock and no additional product, such as ink, coating, or foil, is added to the stock. Including an embossed image or type can enhance the look of a package or other product with little or no environmental impact.

As compared to foil stamping, another way to achieve the glint of metal is by the use of metallised paper. Vacumet, headquartered in Wayne, NJ, USA, is a leading converter of vacuum metallised plastics, papers and holographic metallised papers.Vacumet sells its products to the pressure sensitive laminate converters — Avery Dennison, UPM Raflatac, Green Bay Packaging, Acucote, and others. (www.vacumet.com) metallised papers are less expensive than foils that are laminated to substrates. Another segment in the metallised paper field is of holographic materials. Holographic metallised papers can utilise clean or opaque inks and inks are used to control the show-through of the holographic effect.

Its generally believed that if you have a big label with a small area of foil, it might make sense to use foil stamping, but if it’s a big foil area, it makes sense to use a metallised paper.

Becoming a more sustainable operation goes hand-in-hand with becoming a more efficient operation. After all, who doesn’t want to become more efficient?

Will the packaging you print make it from your finish line to the checkout line?

With more and more printers bringing foil decorating into their pressrooms and statistics showing how foil appeals to consumers when they choose their products, it makes good business sense for package printers to get to know and employ these techniques.

This article was published in Packaging South Asia in March-April 2009 issue.