Just as rap – the hip hop form of dance music – occupies a quirky space between melodious music and poetry, packaging by wrapping too can said to be in a similar space. Just as rapping is a potent form of communicating radical ideas, packaging by wrapping can also be used to radically redefine brand appeal. Just as rapping creates an eclectic aesthetic space of its own, so does wrapping add a unique layer of aesthetics when applied to certain types of products. In fact, the art of wrapping packaging to create unique mind space among customers pre-dates the comparatively recent phenomenon of rapping. However, unlike rapping which has matured enough to be recognized as an art form, the power of wrapping (or rather over-wrapping) – it can be argued – has still to be fully tapped – be it for primary or for secondary packaging.

Ever since the first shop-keepers began to sell produce wrapped in newspaper to bundle and protect, over- wrapping as a form of adding consumer convenience has undergone continuous evolution. Today retailers invariably seek to enhance the quality of retail packaging by the use of over-wrapping. Not only does over-wrapping add much sought-after shelf-appeal but it also helps to provide protection from ‘shop soiling’ as well as tampering. As an added bonus, the film over-wrapping helps to keep out dust and moisture from the product and provides a hermetic seal which assures the customer of the product’s freshness.

Rapping (or emceeing, MCing, spitting bars or rhyming) is ‘spoken or chanted rhyming lyrics.’ Rapping is distinct from spoken word poetry in that it is performed in time to a beat. Rapping is often associated with and a primary ingredient of hip hop music, but the origins of the phenomenon can be said to predate hip hop culture by centuries. Since the early 21st century, it has been possible to hear rap in every major language of the world. Rapping can be delivered over a beat or without accompaniment. Stylistically, rap occupies a grey area between speech, prose, poetry, and singing. Rapping can be traced back to its African roots. Blues music, rooted in the work songs and spirituals of slavery and influenced great- ly by West African musical traditions, was first played by blacks, and later by some whites.

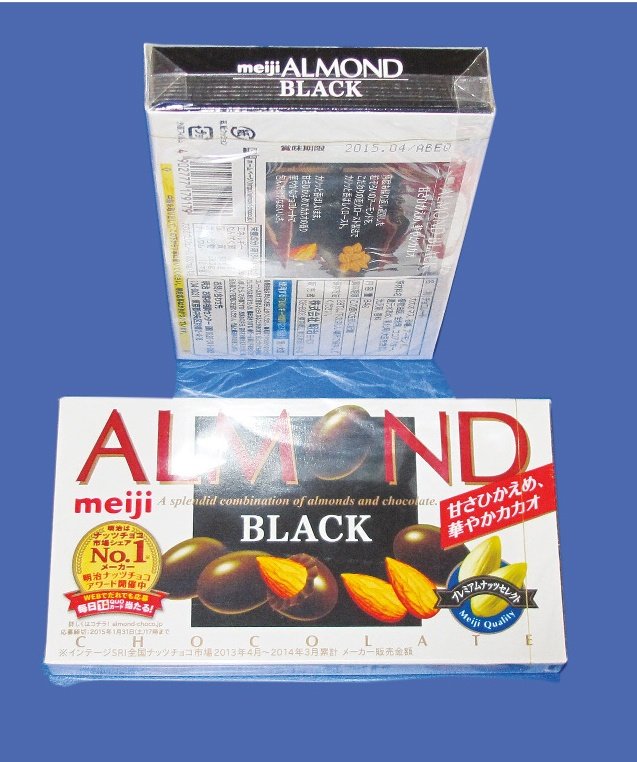

Traditionally, film over-wrapping consists of wrapping a piece of film (or paper) around a single item or a bundle of products and sealing them with diamond point end folds, also referred to as ‘tuck and fold’ or ‘fin seal’ over-wrapping. It produces the same appearance as if the product were wrapped by hand. This is why over-wrapping has appeal for use in the perfume and confectionery industry in particular where many such products are sold to be given as gifts.

Over-wrapping offers a neater and cheaper option in comparison to its better known cousin — shrink-wrapping. For shrink-wrapping, a piece of film about 30% larger than the product to be wrapped is placed over the product and shrunk into place by the use of a shrink tunnel which consumes tens of kilowatts of energy. The end result of shrink-wrapping produces products with jagged edge seals, wrinkles and holes (through which dust can get in). In comparison, over-wrapping requires only the right size of film cut to length and sealed only across the longitudinal seal and end folds using a mere two or three kilowatts of energy. This produces a neat wrinkle free, tightly wrapped product which is hermetically sealed on all sides. An added benefit is that the over-wrapping film — typically oriented polypropylene (OPP) – is thinner and less expensive compared to its equivalent shrinkable clear polyolefin. Over-wrapping cost on the whole, therefore, is lower than shrink-wrap- ping and requires less energy consumption resulting in a lower cost per unit pack.

Over-wrapping has come a full circle

Over-wrapping has customarily been referred to as cello-wrapping. This termi- nology has its origins from the 1950s when all wrapping was done with wood pulp derived clear film called cellophane. The term ‘cello’ is derived from the word cellu lose, which is the primary structural component of green plants. It began to be used for confectionery packaging aslong ago as 1912. Later, cellophane began to be used with a thin coating of plastic to ensure it seals when used for wrapping. In today’s environmentally charged climate, it may be hard to believe that till the mid 1960s wood pulp derived cellophane was the most common form of ‘plastic film’ used for over-wrapping till it began to be replaced by polyethylene which was much cheap- er and at the time considered less environmentally harmful because it saved trees from being converted to cellophane.

LDPE film is strong and ductile enough to run on over-wrapping equipment but it lacks the clarity and gloss of other available film types and for this reason never be came popular as an over-wrapping option. On the other hand, it has gained wide acceptance as shrink-wrapping film for transit pack and bundling applications, including another cousin from the wrapping family – stretch-wrapping. Another problem with the PE family of wrapping films of course is that they are not bio-degradable.

To compete in gloss and workability with cellophane, another wrapping film pop- ular between the 50s to 80s was PVC (polyvinyl chloride). It offered excellent wrap- ping characteristics but concerns about unhealthy toxins produced during its manufacture as well as post-use incineration have led to a drastic reduction in its use.

In recent decades, thin film OPP (oriented polypropylene) has emerged as the film of choice in wrapping applications. It is derived from melting, extruding and stretching or orienting the PP resin which is a petroleum oil derivative. It contains no health or environment hazardous materials making it safe for use with mass consumer products. The resultant film offers excellent strength, barrier and stiffness making it ideal for use on high-speed wrapping machines. The film can be engineered to offer a small (up to 5%) shrinkage after application so as to form a skin-tight finish around a pack without the need for too much heat energy. OPP films are not biodegradable but offer the virtue of assisting combustion of waste when used in an in- cinerator simply to release hydrogen and carbon.

But despite all these film developments, the current global outcry against the use of environmentally polluting poly films by over-wrapping users has resulted in the re-invention of cellulose-based poly films. The cellulose film over-wrap is beginning to return. Film over-wrapping has come a full circle. Polylactic Acid (PLA) film de- rived from corn, sugar cane, straw or wood – which are all renewable sources – have made their appearance. Innovia’s Natureflex wrapping film is based on cellophane and is bio-degradable. Similarly, Tagleef Industries offers Natvia – a PLA-based film. Several other film-makers have similarly developed BOPLA films – 100% plant ori- gin and compostable. In the midst of these developments are the hybridized solu- tions offered by mixing specialized masterbatches and creating oxy-bio-degradable versions of conventional PE, PET or BOPP. Wells Plastics UK offers such a master- batch to create their trademarked Reverte grade films.

Add wrapping – subtract cost

The global economy is a challenge for all producers. There is competitive pressure to save money at all stages of the production and packaging process. Higher energy costs and the vagaries of petroleum product pricing drive up costs of packaging materials and the electricity to run packaging machines as well as the expense of airconditioning and refrigeration systems for both staff and products at safe levels. At the other end of the production process, there are various environment and safety directives (for example – the European Packaging Waste Directive) that make it obligatory for producers and retailers to safely package their goods and thereby in- crease costs of compliance. The popular 3R mantra – reduce, re-use, recycle – makes good sense for the environment, but places the responsibility for product protection, tamper evidence, shelf-life improvement and improved product shelf- appeal on the producer. This can be hard and doing it all as well as saving money in the process can be harder!

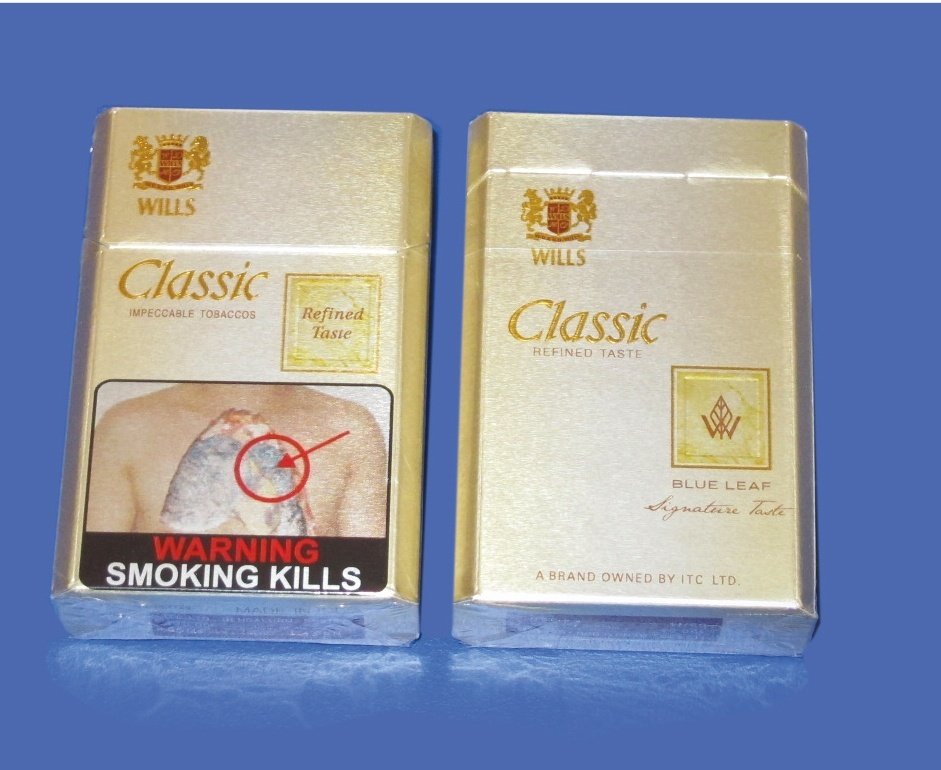

For such reasons the contribution of multi-pack collated over-wrapping as a sub- stitute for intermediate or secondary packaging is being increasingly appreciated. Instead of collating products into a carton or cardboard outer, the over-wrapper forms the collation and wraps the product with either a clear or fully printed piece of film. The cost saving possible by substitution of a unit carton by a sheet of film can be substantial – say as much as 75% less. Evidence of such cost reduction can eas- ily be found in tobacco multi-packs.

Over-wrapping as a substitute for traditional case packing is also possible. Over- wrapping with paper instead of packing in cardboard boxes is proving to be a major potential area of saving. Wrapping with paper of say 200 gsm and sealing the longi- tudinal seal as well as end tucks securely with hot melt adhesive can substitute cardboard box shippers in many cases and in this way reduce overall packing ma- terial weight as well as consequent freight, warehousing and disposal costs.

A weapon of mass attraction

Seen clearly across the haze of time, it may be evident that the potential of over- wrapping as a packaging design tool has been largely under-rated. It may be seen not only as another tool in the shelf-appeal or counterfeit protection armoury but as a potent weapon in the fight against increasing costs. It is time to bring over-wrap- ping out from under the wraps and appreciate its varied roles, namely — perform- ance benefits, cost reduction, environment saving, promotional tool and shelf-ap- peal. Truly a weapon for mass attraction!