The Maharashtra-headquartered SP Ultraflex, a specialist in converting slitter rewinders, will focus on enhancing sustainability through advanced slitting and rewinding technology at this year’s specialty films and flexible packaging summit in Mumbai. The 11th edition of the Speciality Films & Flexible Packaging Global Summit 2024, also known as ElitePlus, takes place on 30 September and 1 October at the Jio World Convention Centre in Mumbai.

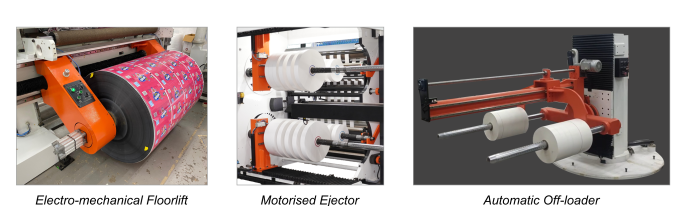

Gatik Arora, senior sales executive and Rohan Pankar, sales engineer – who was part of the company’s entourage at drupa – will showcase SP Ultraflex’s innovations such as electro-mechanical linear floor lifts, automatic job setup, dual turret rewind systems, motorized ejectors for finished reels, automatic off-loading solutions, and cartridge systems for easy cutting mode changeovers.

These features are designed not only to align with broader sustainability objectives but also to increase profitability by improving efficiency, reducing waste, and enhancing operator friendliness, company officials told Packaging South Asia.

“As for new products and innovations, SP Ultraflex views innovation as a continuous process. The company has focused on addressing production bottlenecks and waste management challenges in the last eight months. This has led to updating features such as automatic job setup with pick-and-place mechanisms, the Magic Trim Box, in-line trim chopper, and more,” Arora said.

Speaking on the company’s expectations from this year’s summit, Arora said SP Ultraflex sees this year’s summit as an opportunity to exchange ideas and inspire converters to expand their sustainability efforts by integrating technological advancements with process and material innovations. “Additionally, we aim to gain insights into emerging market trends, which will help guide our R&D activities in the coming year.

Focus on sustainability

SP Ultraflex, the officials said, addresses sustainability, plastic circularity, recycling, and EPR regulations through advanced features integrated into its slitting and rewinding machines. The company’s equipment, they explained, is engineered to minimize waste, optimize material usage, and enhance the recyclability of packaging materials.

“For instance, our trim handling systems effectively manage waste and reduce machine downtime. By emphasizing versatility and efficiency, our machines not only support the principles of plastic circularity but also comply with the stringent requirements of extended producer responsibility (EPR) regulations such as handling new, more recyclable substrates such as MDO PE, thereby promoting a more sustainable packaging industry,” Pankar said.

Elaborating on recyclability and MLPs, Arora said the shift toward mono-material from multi-layer films is still in development, with the industry increasingly exploring substrates such as MDO PE, which offer better recyclability. However, this transition presents its own set of challenges, he said. “As slitter and rewinder machine manufacturers, we have validated our equipment for use with these new substrates. Additionally, recycling machines for MLPs have gained popularity recently. In summary, whether the industry will fully transition to mono-materials or adopt advanced recycling technologies for existing MLP substrates remains to be seen. Nevertheless, we are prepared to support both scenarios.”

Automation for efficiency

So how does the company foresee the use of AI, IoT, and robotics for efficient packaging? SP Ultraflex, the officials said, is at the forefront, incorporating cutting-edge technologies such as intelligent tension management (ITM) and industrial internet of things (IIoT). These advancements provide precise control, predictive maintenance, and real-time process optimization, significantly boosting operational efficiency, minimizing downtime, and enhancing overall effectiveness, they said.

“In the realm of robotics for efficient packaging, we offer sophisticated solutions such as automatic job setup and floor-to-conveyor systems. These innovations improve productivity and safety, reduce operator fatigue, and ensure accuracy in repetitive tasks, embodying the core benefits of robotic integration,” Arora said.