Faridabad-based RK Printers, a corrugated carton provider supplying to the pharmaceutical, cosmetics, and food & beverage industries, claims to have achieved a milestone with a 20% growth in sales Y-o-Y in 2023 in comparison to 2022. The company manufactures monocarton and corrugated carton packaging with UV coating, embossing, spot and raised UV, aqueous coating, braille along with other special decorative effects.

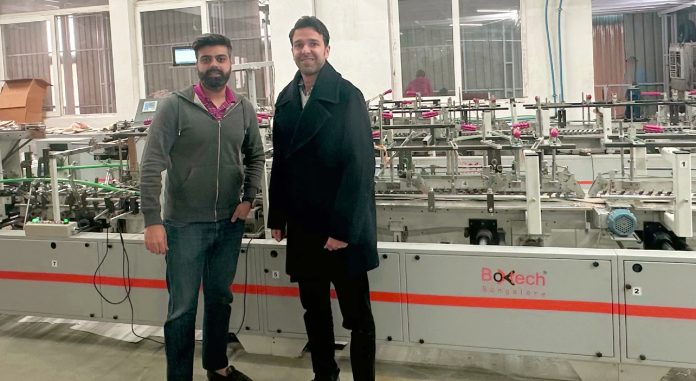

Partners Vikrant and Akshay Malik are the next-generation managing directors of the company that began its journey in 1972. Started by three brothers, KS Malik, Rakesh Malik, and Ramesh Malik, the company was among the few printers in Delhi with offset presses for publishing and packaging in the industrial sector of Delhi’s Anand Parbat area. The company later shifted to Faridabad.

The drive to the production plant located in the IMT area took longer than expected due to the ongoing construction of the Delhi-Mumbai expressway, which cuts through Faridabad. Construction of the high-speed road, which will cut travel time between the national and financial capitals, and was expected to spur economic activity along the route, has reportedly been delayed.

At the production plant, Vikrant told Packaging South Asia about the company’s successful expansion in 2023 to meet the growing demands of the market via capacity addition, which includes a crash bottom pasting machine, a double color printer slotter corrugation machine, and a big pasting machine. The company utilizes two Heidelberg 6-color coaters for printing and several converting equipment from Bobst and BoxTech.

Vikrant said, “In the pharmaceutical sector, we provide specialized packaging solutions, ensuring the safety of medical products. For the bakery industry, our packaging caters to preserving the freshness. In FMCG, our solutions align with the dynamic packaging needs of consumer goods. In the cosmetics industry, we offer aesthetically pleasing and functional packaging solutions.”

The expansion of RK Printers involved increasing its production capacity, exploring new markets, and enhancing its distribution network. “We identified opportunities to reach a wider customer base and positioned ourselves for sustained growth. Our expansion efforts are ongoing, with plans to invest in additional resources and facilities to further strengthen our presence in the packaging industry,” Vikrant said.

Elaborating further, Akshay said, “Our market penetration extends nationally and internationally, with a strong presence in North India to meet the unique demands of each sector. We are thrilled to announce our ISO certifications —a testament to our commitment to quality. We are certified with the ISO 9001:2015 (quality management system), ISO 14001:2015 (environmental management system), and ISO 45001: 2018 (occupational health & safety management system) standards. We plan to enter the export market.”

According to the partners, within the Indian markets, the most interesting solutions currently revolve around sustainable packaging, smart packaging technologies, and customization options that meet the needs of consumers and industries. The company is implementing eco-friendly practices such as using recyclable materials and is trying to minimize its environmental footprint.

Vikrant said, “We have solar panels in our factory operations, which helps in reducing our carbon footprint. By decreasing reliance on conventional energy sources and opting for renewable energy, our goal is to implement environmentally conscious practices in the packaging industry.” The company has also installed a rainwater harvesting plant.