ExxonMobil, collaborating with value chain partners Amcor India and Syntegon India, has developed a recyclable* full polyethylene (PE) laminated detergent packaging solution to replace existing PET/PE laminated packaging, which are not easy to recycle. The solution maintains mechanical and optical packaging performance required for detergents and was jointly developed with Amcor, a leading film converter, and Syntegon Technology India Private Limited, a leading supplier of packaging machines, .

“Packaging recyclability has grown in importance in India in recent years with the publishing of Plastic Waste Management Rules in 2016, which require non-recyclable multi-layer packaging (MLP) to be phased out,” said Sita Parasuram, market developer, ExxonMobil. “With at least one layer of plastic combined with one or more layers of other materials such as paper, paper board, polymeric materials, metalized layers, or aluminum foil, MLPs can be difficult to mechanically recycle. ExxonMobil has helped to take on the challenge by replacing MLPs films with recyclable full PE laminated solutions for varying applications.”

Challenges in print, converting, filling, and sealing

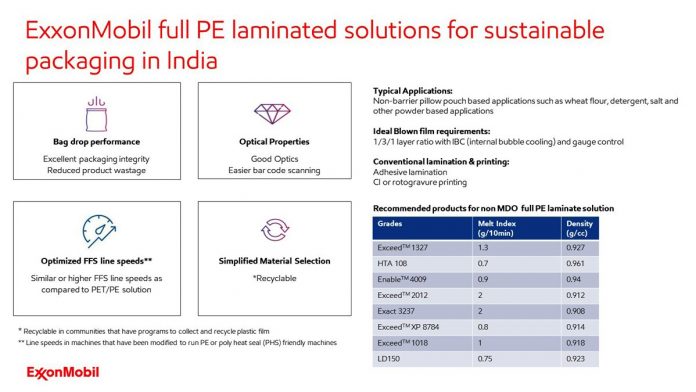

Several challenges may need to be overcome in changing from a PET/PE laminate to a full PE laminated solution. These include ease of printing on PE substrates, a significant drop in packing line speeds, unsatisfactory optics, sealing requirement changes, and changes in machinery that can lead to high costs.

“The challenge was to develop a technical solution for full PE laminates which maintained mechanical and optical performance while enabling the desired printing and packaging equipment line speeds,” said Nilesh Shah, technical advisor, ExxonMobil. “ExxonMobil leveraged a ‘design for recyclability’ approach to help drive the change in the packaging from a multi-material to a mono-material structure, in this case, a full PE solution.”

Working collaboratively, ExxonMobil, Amcor, and Syntegon developed a recyclable full PE laminated detergent packaging solution that maintains mechanical strength, seal integrity, and optical performance. Amcor produced the PE substrate/top film and the PE sealant film using ExxonMobil’s performance PE polymers ― including Exceed XP 8784, Exceed 2012, Exceed 1327, and ExxonMobil HDPE HTA 108 ― which ensure performance is maintained. Amcor then converted the films into laminates without modifying machinery. Syntegon converted these laminates into packs using vertical form fill seal (VFFS) machines modified to be poly heat seal friendly, so the packs were made without any challenges.

PE laminated food application developed with Shrinath Rotopack

“Naturally, we are delighted with the success of this collaboration with Amcor and Syntegon,” said Hari Gusain, manager of Area Sales, ExxonMobil. “It follows the recent introduction of another successful full PE laminated solution developed with Shrinath, another leading converter in India, and Syntegon, for salt packaging applications.”

* Recyclable in communities with programs and facilities in place that collect and recycle plastic films.