Digital print’s potential to improve production efficiency and enhance emotional engagement with consumers has long been touted in the print industry. However, with it now increasingly also being recognized by designers, brands and retailers, the market is forecast to grow at almost 10% through to 2034, according to Towards Packaging. And with the Asia-Pacific region already making up almost 21% of digitally printed packaging’s global market share, this disruptive technology is here to stay.

Alongside its suitability for short runs, customization and quick reactions to fleeting consumer trends, digitally printed packaging also has a strong appeal for brands needing to instantly respond to legislative changes or incorporate track-and-trace, as well as those who want to add brand protection features. Add to all of this the technology’s appeal for brands focused on reducing waste, as well as suitability for the small-batch packaging demanded by the e-commerce market, and its appeal is unmistakable.

Numerous disruptive technological developments have enabled the explosive growth of digital print for packaging, but one that stands to truly revolutionize packaging is direct-to-object or direct-to-shape printing. This low-inventory method puts greater control of the supply chain in the hands of producers, something that has an obvious appeal for manufacturers concerned about supply chain issues and sustainability. In addition, it has the potential to reduce the need for labels and shrink sleeves, and stands to significantly reduce costs.

Direct-to-object printing for glass bottles

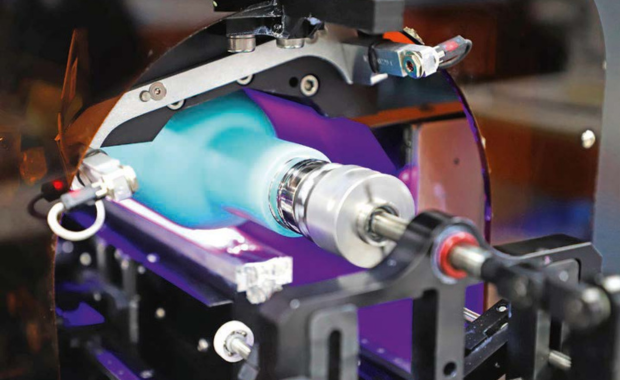

Digitally printing directly onto the glass itself is typically associated with coding applications, with labeling and decorative artwork done using printed adhesive labels or shrink sleeves. However, direct-to-object digital print makes it possible to print photographic quality artwork directly onto 360° of a bottle in run lengths as low as one. Cylindrical direct-to-bottle inkjet printers such as Inkcups’ Helix range even make it possible to print onto pre-filled bottles.

Direct-to-bottle printing opens up numerous opportunities for craft distilleries, microbreweries, boutique wineries, non-alcoholic mixed drink makers, and other independent beverage producers to print their bottles on-site. For larger producers, the technology’s suitability for one-off and small-batch production makes it ideal for capitalizing on the consumer appetite for personalization by offering customized bottles as gifts, as well as for rapidly responding to social media and seasonal trends with limited edition campaigns.

Photographic quality and special effects

With alcoholic and non-alcoholic beverage markets becoming increasingly competitive as they vie for consumer attention, creating eye-catching packaging, conveys brand values, and is still cost-effective to produce has become something of a balancing act. These are not markets with a strong amount of brand loyalty, but where purchasing decisions are made at the shelf and packaging design can be very persuasive.

For medium and low-volume beverage producers, direct-to-bottle digital printing opens up a world of creative possibilities. With photo-quality print, designs can be as creative as with digitally printed labels, but with the seamless print delivered by cylindrical inkjet printing eliminating any concerns about distortion or stretching during application, the result will be even more striking. In addition, while digital print has long been known for high image quality, continuity of tone, wide color gamut and precise text, direct-to-object inkjet printing also opens up the possibility of creating tactile effects with spot varnish or by varying ink opacity.

Tone-on-tone varnishing, for example, can be used to create an embossed effect on glass, while an etching effect can be achieved by using white ink at a lower opacity. Even stained glass effects are made possible by printing color only and allowing light to shine through. The only limit is the designer’s imagination.

Sustainability and the shift to a circular economy

By enabling the production of striking graphics directly onto a bottle, direct-to-object printing makes it possible to achieve visually appealing cylindrical packaging without any need for adhesives, labels or shrink sleeves, simultaneously eliminating waste from the decoration process and making end-of-life recyclability easier for the consumer. Given the strong recyclability credentials of glass bottles, this stands to be an increasingly strong selling point as both consumers and regulators look for packaging to become more sustainable. In addition, with supply chain sustainability under growing scrutiny, lean in-house packaging production may now hold greater appeal, particularly for small and medium-sized manufacturers.

(Ryan Quinn is global sales & business development, Inkcups. The views expressed in this article are personal)

Inkcups is a supplier and manufacturer of digital inkjet equipment, pad printing equipment, laser platemakers and corresponding supplies, with direct sales, technical support and warehouse locations in the USA, Mexico, Germany, Hong Kong and other global locations. Inkcups manufactures industrial machines for a wide range of industries, including apparel, drinkware, promotional, electronic, medical, sporting goods and automotive markets.